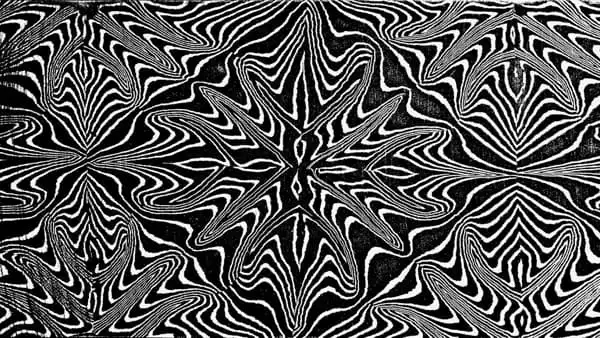

Charming damask steel mosaic patterns

Damascus steel mosaic

Damask steel mosaic is a popular type of steel that is easily identifiable by its light dark watery or wavy metal pattern. It is known that damask steel mosaic is made by the technique of repeated forging welding of plates that differ from each other in their chemical composition and therefore the color changes after engraving.

How to make Damascus pattern?

It is necessary to take carbon steel and steel with a high content of nickel (or pure nickel). Damascus steel patterns vary depending on how the craftsman worked with the workpiece. damask steel mosaic is made of several types of steel welded together in a vacuum.

Known for its exquisite designs and patterns, this steel is available and is often used today in making Damascus knives and daggers. It requires the best steel to make it stable and flexible.

Using two successive types of steel, the blacksmith heats, mounts, and stacks layers of metal to create vibrant patterns. In damask steel mosaic patterns, some steels are white or glossy, some are shades of gray and some are black. Experienced blacksmiths can create many different patterns while forging. Then the blade must be hardened.

Steel damask mosaic

Steel damask mosaic is much more difficult to manufacture than the usual Damascus.

The “mosaic” is also made by forging from multi-colored steel and this method is very old. The Damascus steel mosaic pattern is obtained with a special symmetrical arrangement of voids from different types of steel. To assemble this mosaic, not only boards are used, but also specially made rods of very complex cross section. Depending on the specific arrangement of these dissimilar elements, the cross-sectional pattern of the embossed welded block can be very complex. The pattern, which is easy to manufacture, is formed when a block of bars and panels of rectangular cross-section is assembled.

Examples about damask steel mosaic

Good examples are patterns such as “chessboard” and “star” otherwise “occasional”. Welding such a block is not difficult, very often used by manufacturers of rifle barrels. The same level of complexity is a “lattice” mosaic obtained by welding a briquette of several steel bars of square cross-section within nickel plates placed between them.

Damascus mosaic box

It is more difficult to manufacture a block with a complex ornament, such as letters, multi-beam stars and the like. Original blocks with such patterns can be welded into a monolith, using only special mandrels and bushings; Otherwise, a group of heterogeneous fibers will scatter during the molding process. Composite steels are made by placing hard, powdered steel in a metal case and fusing them together using forging welding using heat and pressure.

Custom damask steel mosaic patterns

A more advanced technique used by modern craftsmen is to weld mosaic blocks with realistic images of people and animals. To assemble the original beam itself, rails are used, in which the shape breakers are made by the method of electro-corrosion. These rods, which act as matrices, are inserted into the cut-out shape gaskets made of another dissimilar metal. After welding and carefully shaping the original intricate embossed block, the only thing left is to show this complex pattern, that is, somehow transfer it to the side surfaces of the knife blade block. Sharply heterogeneous, large-patterned mosaics rarely have good cutting properties on their own. To give the knife good cutting properties and wear resistance, it is combined with multilayer Damascus. Craftsmen use three main methods to display the damask mosaic pattern, resulting in quirky, exposed, and finished mosaics.

This isn’t just a mosaic – it’s a forge-welding masterpiece and an art itself

The value and meaning of the damask steel mosaic is not limited to its makers and craftsmen only, but also has a cultural value that reflects an image of ancient Damascus.